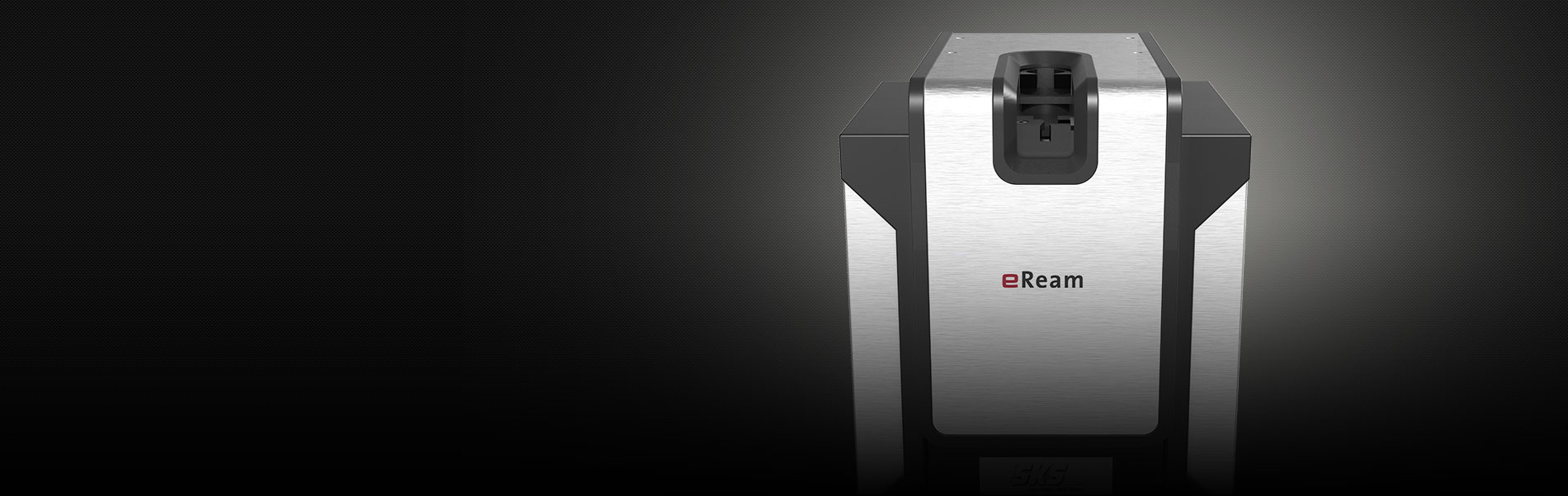

eReam: Pure electric

The eReam torch cleaning station by SKS sets completely new standards with its purely electric drive

In automated arc welding, torch cleaning affects both the cost and productivity of the whole process. To positively influence both factors, the eReam innovative torch cleaning system of SKS offers striking benefits. Its all-electric drives save considerable amounts of energy compared to pneumatic drives, are easier to control, comply with the applicable safety regulations and offer good monitoring capabilities.

An easy-to-handle cleaning of the gas nozzles, reliable operation and system integration are among the basic features of eReam. Low energy costs are another asset of the system. Compared with pneumatically driven torch cleaning devices, the cost of energy is much lower.

A simple integration without expensive security hardware, energy and resource saving as well as an effective cleaning were the basic requirements of the development. Electricity instead of compressed air, combined with the proven cleaning with reamers, paved the way for this innovative cleaning system.

Learn more about our Reamer Blades

Downloads

With the optional wire cutting unit the wire is placed on a freely definable stick-out.

The centering of the gas nozzle is done with a centering ring which precisely positions the gas nozzle for the milling process.

Clamping jaws hold the gas nozzle to the cleaning position, until the reaming process is completed.

The cutter moves up and frees the contact nozzle from dirt and weld spatters. From 15 mm gas nozzle diameter on, it is cleaned up to the nozzle assembly.

The scrapings are passed through a chute into a collecting tank.

To increase the operational time, a anti-spatter linquid may be used to protect the gas nozzle against contamination with dirt after the reaming process. This is applied with dosed impulses on the gas nozzle.

eReam is ready for integration with its diverse programming options and its open interface for robot and fieldbus environments

Product types

Product types

Basic unit

+ injector

centering

clamping

reaming

sprayingBasic unit

+ injector

+ wire cutter

cutting

centering

clamping

reaming

sprayingFeatures

- First fully electric driven cleaning system

- Processes driven by individual motors

- Operation without compressed air

- Ejection of cleaning residues at bottom side

- Automated monitoring of limits within the cleaning process

- Fully electronic adjustment/setting

- Control of external air blast valves

- Digital I/Os / Fieldbus (in preparation)

- Full integration into facility control possible (setting up, controlling, monitoring)

- Includes TCP programming tip

Connections

Connector 1:

12 pin chassis connector

Control signals for eReam

is connected to PLC/robot control cabinetConnector 2:

5 pin socket

Air blast valve control robot 1

Connecting line to the Air blast valve control of robot 1Connector 3:

5 pin socket

Air blast valve control robot 2

Connecting line to the Air blast valve control of robot 2Connector 4:

5 pin socket

Supply line (connecting cable +24 VDC and enable signal from the robot) Connection to PLC/robot cabinetFieldbus connection: in preparation

Technical specifications

Basic unit with injector

- Gas nozzle outer diameter max: 34 mm

- Cleaning cycle duration: ~ 4 s

- Supply voltage: 24 VDC

- Maximum power consumption: 100 W

- Weight ( basic version ): 13 kg

- Dimensions in mm ( L / W / H): 305 / 270 / 370 mm

Optional accessories:

- Gas nozzles specific reamers

- Stands for cleaning equipment

- Collecting tank for cleaning residues

- Power and control cables

- Anti-spatter liquid (containers, each 5 liter)

- External power supply 24 VDC for DIN rail mounting

Basic unit with wire cutter and injector

- Gas nozzle outer diameter max: 34 mm

- Cleaning cycle duration: ~ 5 s

- Supply voltage: 24 VDC

- Maximum power consumption: 125 W

- Weight ( basic version ) : 15 kg

- Dimensions in mm ( L / W / H): 305 / 270 / 370 mm

Optional accessories

- Gas nozzles specific reamers

- Stands for cleaning equipment

- Collecting tank for cleaning residues

- Power and control cables

- Anti-spatter liquid (containers, each 1 liter)

- External power supply 24 VDC for DIN rail mounting

Technical specifications of eReam

Control

A purely electric drive provides data on state of the motor, speed and load. An unprecedented precision and control of the cleaning process is achieved by an integrated intelligent motor control. The evaluation of information also facilitates handling. While a pneumatically operated system provides no feedback when a reamer is canted and stops, with a purely electric system the motor gives feedback, the reamer can be re-centered and the cleaning process can be continued.

Safety at work

Compressed air for pneumatic drives is costly to control via valves. Since the pressure is only reduced with a significant time delay, a complex safety technology is required. This is where the benefits lie. These can be stopped easily with less technical effort and provide information about their condition within milliseconds. Beside the technical advantages, additional investment is waived for a costly security technology.

Environment / Resources

Electric motors have an efficiency of over 90 percent, while the energy for pneumatic drives is subject to high losses in production. So air must first be compressed, with high losses of heat. This additional energy is saved with using electricity, getting the effect of lower operating costs. To conserve resources, the pump for spraying the anti-spatter liquid has been provided with an electronic control system for accurate dosing. The saving of anti-spatter liquid has a positive effect on operating costs.

Simple Integration / manageability

Simple "Start - Drive - Save" programming allows a quick and easy set up. With the additional I/Os control tasks for up to two external air-blast valves can be implemented.

Future-proof design

Binding equipment guidelines to ensure a uniform level of protection for accident prevention. These are regularly redefined and applied considering new findings and according to the latest technical level. eReam already satisfies with its all-electric cleaning principle possible future regulations, thus saving a considerable investment in retrofits.

Benefits - SKS eReam

- Pure Electric: Pure electrically driven eReam provides a precise and controllable cleaning.

- Electric Power: Cutting, centering, clamping, reaming, spraying

- Easy Integration: Simple integration without expensive security hardware

- Energy and resource saving and an effective cleaning were the basic requirements of the development

- Electricity instead of compressed air in addition with the proven cleaning with reamers, paved the way for this innovative cleaning system.